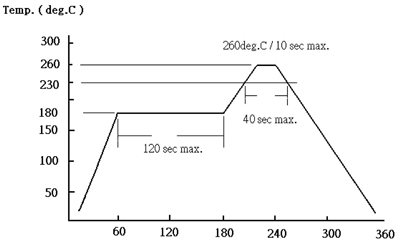

In general, though, it makes sense to use the profile that accompanies your chosen solder paste-your PCB has a variety of components but only one type of paste, and the manufacturer knows what sort of temperatures will make the paste do its thing. If your board includes one component that is more important or temperature sensitive than all the others, perhaps you should follow the recommended profile for that component. Obviously, if four different parts on the same board all come with different profile recommendations, you can’t please them all. Sometimes the datasheet for an individual part will include a recommended profile. The first step, of course, is deciding which profile to follow. So I think it’s well worth the time and effort to develop a procedure that allows you to replicate a profile with reasonable accuracy. I’m sure it is possible to successfully reflow a PCB without adhering to the profile, but I highly doubt that the results are consistent or of particularly high quality. Manufacturers do not formulate and publish reflow temperature profiles simply to entertain themselves.

#REFLOW SOLDERING TEMPERATURE PROFESSIONAL#

Professional assembly is rarely a feasible option: it is surprisingly expensive, especially for small quantities, and coordinating with the assembly house can be awkward if you are trying to use whatever stray components you have lying around your lab/office/garage/bedroom.

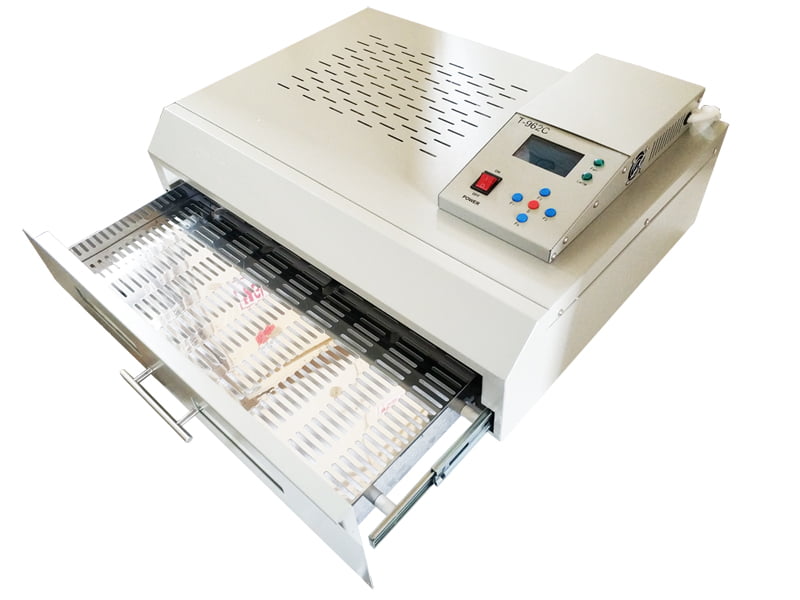

Hand soldering is becoming increasingly burdensome-sometimes impossible-owing to the proliferation of miniscule components, leadless packages, and ball-grid arrays. This temperature feedback will enable you, the assembly technician, to accurately control the oven’s heating profile via simple, real-time adjustments.Īs you may know, surface-mount assembly can be a serious impediment for students, hobbyists, entrepreneurs, or anyone else who wants to design and test high-performance circuit boards without paying for professional assembly.

In short, the system displays the current temperature and a graph representing the temperature history, as follows:

#REFLOW SOLDERING TEMPERATURE HOW TO#

That article tells you how to build and use the system, and it provides links for downloading the microcontroller code and the Scilab script. In a previous article ( Make an EFM8-Based System for Monitoring and Analyzing Thermocouple Measurements), we developed an EFM8-and-Scilab-based system for collecting, recording, and displaying thermocouple temperature measurements. With the help of a DIY thermocouple measurement system, you can use a cheap toaster oven to accurately reproduce a reflow-soldering temperature profile.

0 kommentar(er)

0 kommentar(er)